A flexographic printing plate (made of photopolymer or rubber) is a printing plate that transfers ink to the substrate to reproduce a design. It is the key element of flexographic printing, used to manufacture containers, labels, newspapers, and packaging of all kinds.

What is a cliché in flexography?

In flexographic printing, the printing plate (also called the flexographic plate ) is the piece that contains the embossed design. As it rotates in the press, it picks up ink from an anilox roller and transfers it directly onto the material to be printed (paper, cardboard, plastic, film, etc.).

Clichés are fundamental to mass production because they allow thousands of identical copies of the same design to be reproduced with great consistency and speed.

Types of clichés in flexography

Photopolymer plates

They are the most common option in the industry today. They are manufactured by exposing a layer of photopolymer to UV light through a film with the design. The exposed area hardens and forms the embossed image, while the unexposed area is removed by washing (with water or solvent).

- Advantages: high resolution, fine details, sharp lines and durability (between 5,000 and 50,000 prints).

- Uses: high-quality packaging, labels, food containers.

Rubber (elastomer) clichés

Less common nowadays, but still used for specific applications. They are softer and adapt better to irregular or textured substrates.

- Advantages: flexibility, good adaptation to uneven surfaces.

- Durability: up to approximately 10,000 prints.

- Use: printing on corrugated cardboard, sacks, non-flat surfaces.

Rubber cliché for flexographic printing

How is a cliché made?

The creation of a photopolymer plate follows these steps:

- Design preparation: digital artwork is created with color separation (one cliché for each print color).

- UV exposure: a negative film is placed on the photopolymer plate and exposed to ultraviolet light. The areas exposed to light harden.

- Washing: The plate is immersed in water or solvent to remove the unhardened photopolymer, revealing the embossed design.

- Drying and curing: the board is oven dried and receives a final UV exposure to complete the hardening process.

- Mounting: The finished cliché is mounted on the cylinder of the flexographic press.

Flexographic printing presses with mounted clichés

How much does a flexographic printing plate cost?

The price of a cliché varies depending on several factors:

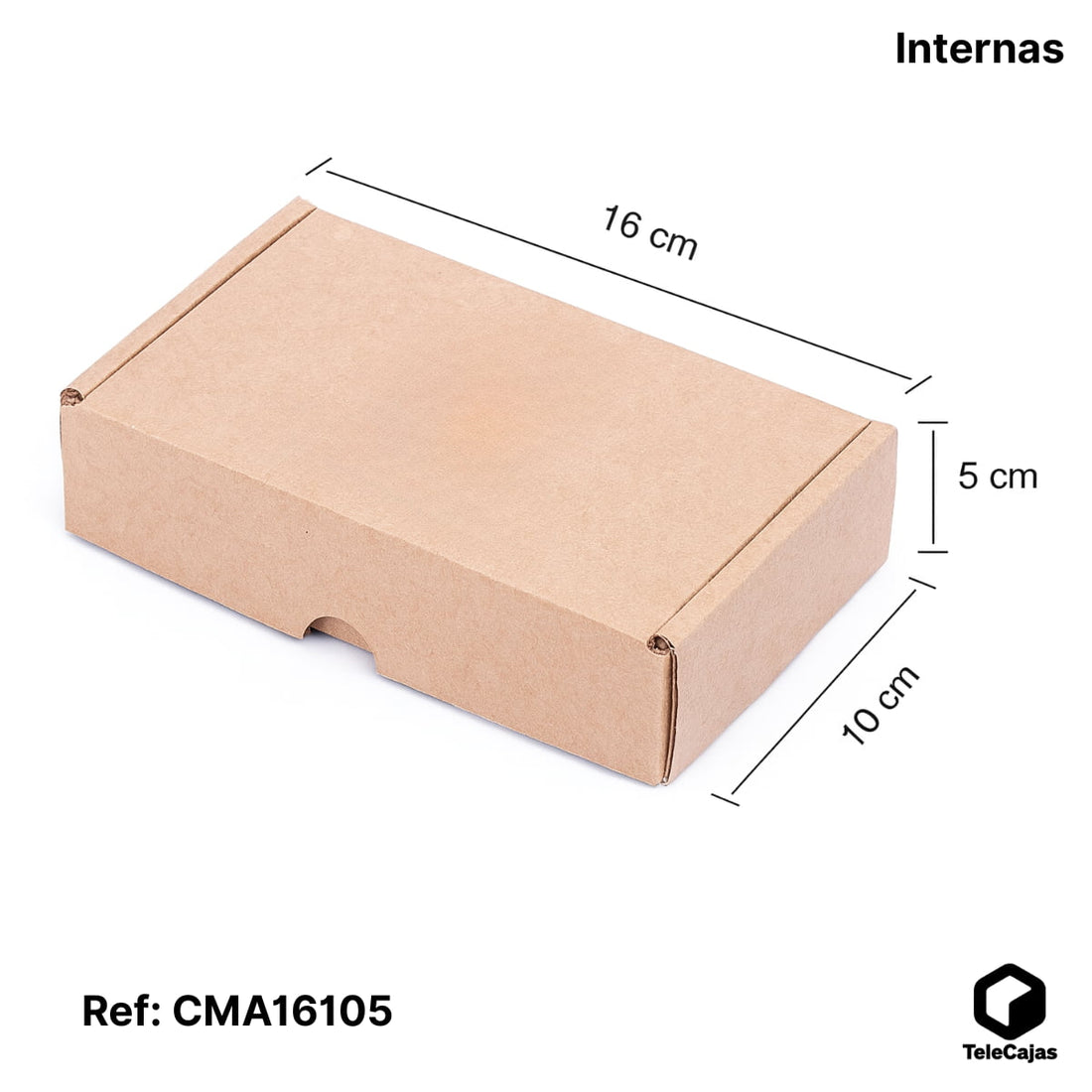

- Plate size: the larger the printed area, the higher the cost.

- Number of colors: one cliché is needed for each color, so a 4-color print requires 4 plates.

- Resolution: Designs with fine patterns or complex details require higher quality printing plates.

- Type of material: photopolymer is usually more expensive than rubber, but lasts longer.

As a general guide, a set of printing plates for a standard cardboard box with 2-3 color printing can cost between €150 and €500 , although for large or highly complex jobs it can exceed €1,000.

Why are clichés important?

A good quality printing plate is essential for achieving a sharp and consistent print. If the plate has defects, the resulting image will be blurry, uneven, or have ink flaws. This is especially critical in:

- Food packaging: where regulations require clear legibility of nutritional information and dates.

- Branded packaging : where visual quality reflects the company's image.

- Labels: where barcodes and small text must be perfectly legible.

Care and maintenance of printing plates

- Storage: Store in a cool, dry, dark place away from direct sunlight.

- Cleaning: Clean regularly with mild solutions and a soft brush after each use.

- Inspection: Check periodically for wear, scratches, or deformations that affect print quality.

Frequently Asked Questions

Are clichés reusable?

Yes, flexographic printing plates are reusable. Their lifespan depends on the material and care: photopolymer plates can last between 5,000 and 50,000 prints.

How do you choose the type of cliché?

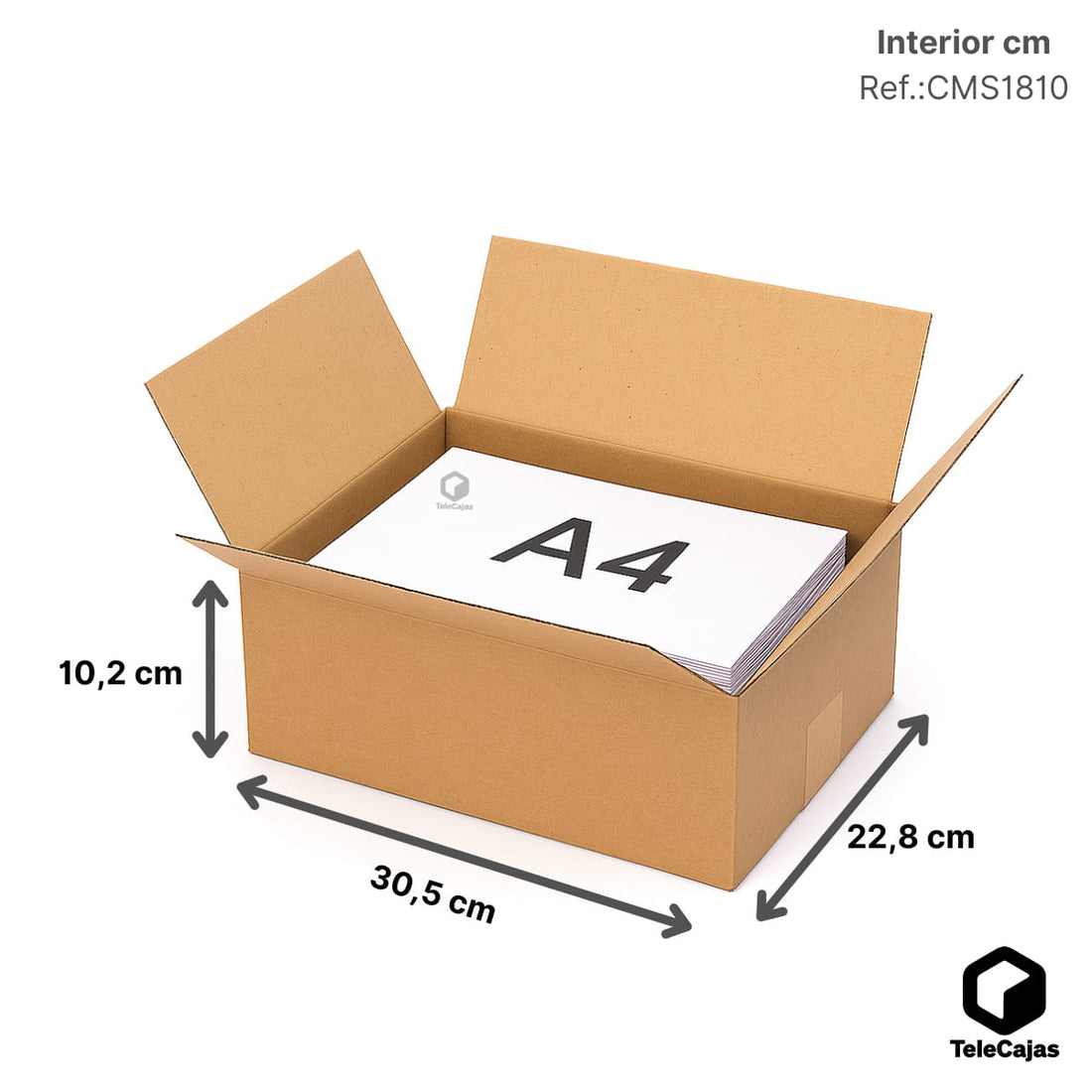

The choice depends on the substrate (cardboard, plastic, paper), the required resolution, and the production volume. For corrugated cardboard boxes , rubber printing plates remain a viable option due to their adaptability to irregular surfaces.

What happens if a cliché gets damaged?

It must be repaired or replaced immediately to prevent defective production. Some minor defects can be repaired, but significant damage requires manufacturing a new iron.

Hola, al investigar un poco hemos dado con estas dos empresas Ctpcprint y Macrolit. Suerte!

Hola podrían orientarme de conde fabrican clichés en México, me interesa encontrar quien fabrique los clichés. gracias