The PAP 20 symbol: Current regulatory framework and evolution under the PPWR

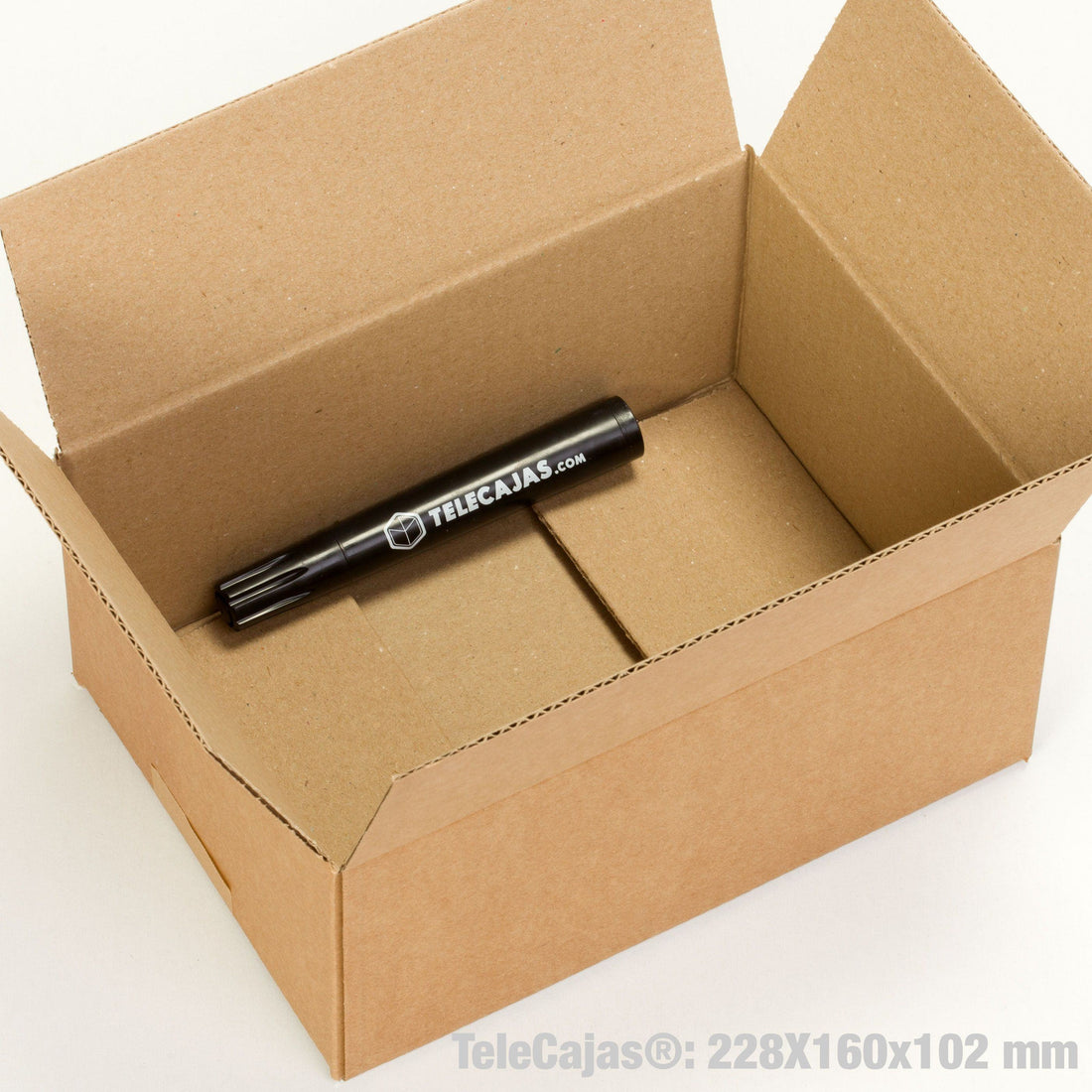

The code 20 PAP identifies corrugated cardboard within the European coding system for packaging materials. Established by Directive 94/62/EC, this symbol is a key tool for material traceability and the proper end-of-life management of packaging.

For sustainability professionals, understanding this coding system—and the changes brought about by the new PPWR Regulation—is essential to ensuring regulatory compliance and optimizing circular economy strategies.

Composition and classification of the symbol

The symbol 20 PAP is composed of:

- Möbius triangle : Indicates recyclability of the material

- Numerical code "20" : Specific identifier for corrugated cardboard according to DIN 6120

- Abbreviation "PAP" : Derived from the German "Papier", it categorizes the material within the cellulose family.

Within the PAP family, the codes are distributed as follows:

| Code | Material | Typical applications | Current recycling rate (EU) |

|---|---|---|---|

| PAP 20 | Corrugated cardboard | Secondary packaging, transport boxes | ~92% |

| PAP 21 | Compact cardboard | Consumer packaging, premium packaging | ~85% |

| PAP 22 | Paper | Bags, office paper, wrappers | ~74% |

Current regulatory framework: Directive 94/62/EC

Under the current Directive, the use of the 20 PAP symbol is voluntary at European level , although some Member States have made it mandatory:

- Italy : Mandatory since Legislative Decree 116/2020. Requires environmental labeling on all packaging.

- Bulgaria : Mandatory for packaging intended for the national market.

- France : The use of the Triman logo is mandatory, along with separation instructions.

Practical implication : Companies exporting to these markets must include the 20 PAP symbol on their corrugated cardboard packaging, regardless of the regulations of their country of origin.

The paradigm shift: PPWR Regulation (EU) 2025/40

The PPWR Regulation , in force since 11 February 2025, replaces Directive 94/62/EC and fundamentally transforms the packaging management framework in the EU.

Key differences compared to the previous Directive

| Aspect | Directive 94/62/EC | PPWR Regulations |

|---|---|---|

| Legal nature | Directive (requires transposition) | Regulation (direct application) |

| Labeled | Voluntary (national exceptions) | Mandatory and harmonized |

| Recyclability criteria | Not defined at EU level | A/B/C system with minimum thresholds |

| REP Rates | At the discretion of each State | Mandatory eco-modulation |

New harmonised labelling system (Art. 12 PPWR)

From 12 August 2028 , all packaging marketed in the EU must comply with the new harmonised labelling system:

Mandatory components

- Unified pictograms : Standardized designs for the entire EU that will gradually replace national symbols

- QR Code : Link to digital information on composition, recyclability and separation instructions

- Recyclability classification : Indication of level A, B or C of the packaging

Recyclability classification system

The PPWR introduces a system for evaluating recycling performance:

- Level A : Recyclability ≥95% — Maximum efficiency

- Level B : Recyclability 80-94% — Standard compliance

- Level C : Recyclability 70-79% — Minimum threshold

Critical ban dates :

- 2030 : Ban on the marketing of packaging with <70% recyclability

- 2038 : Ban on the marketing of packaging with <80% recyclability

Corrugated cardboard (20 PAP) generally achieves A or B levels when properly designed, which positions it favorably in relation to these requirements.

Eco-modulation of REP tariffs

The PPWR establishes that Extended Producer Responsibility fees should be adjusted according to the actual recyclability of the packaging:

- Highly recyclable packaging (Level A): Reduced rates

- Packaging with low recyclability (Level C): Increased rates

- Packaging with recycled content : Additional bonuses

This structure creates a direct economic incentive to optimize packaging design towards recyclability.

Quantitative targets for paper and cardboard

The PPWR sets specific targets for the cellulosic materials category:

- Recycling rate 2030 : 90% for paper and cardboard

- Minimum recycled content : To be defined in delegated acts (requirements expected by 2030)

- Reuse objectives : Applicable to certain transport packaging formats

Compliance checklist for sustainability professionals

Short term (2025-2027)

- ☐ Audit the current packaging portfolio and identify all PAP 20, 21 and 22 materials

- ☐ Verify compliance in markets with mandatory labeling (Italy, Bulgaria, France)

- ☐ Evaluate the actual recyclability of current packaging according to PPWR criteria

- ☐ Identify packaging at risk of falling below the 70% threshold by 2030

Medium term (2027-2028)

- ☐ Implement infrastructure for QR codes on packaging

- ☐ Adapt packaging designs to the new harmonized labeling system

- ☐ Establish traceability systems to report recycled content

- ☐ Review contracts with packaging suppliers to include PPWR requirements

Long term (2028-2030)

- ☐ Ensure that 100% of packaging complies with harmonised labeling

- ☐ Optimize designs to achieve Level A or B recyclability

- ☐ Implement eco-design strategies to minimize REP fees

- ☐ Document and communicate the environmental performance of the packaging portfolio

Corrugated cardboard as a strategic material

Within the new PPWR framework, corrugated cardboard (20 PAP) presents significant competitive advantages:

- High existing recycling rate : ~92% in the EU, already exceeding the 2030 target

- Consolidated collection infrastructure : Established network of containers and collection systems

- Mature recycling chain : Sufficient industrial capacity to process the material

- Biodegradability : A favorable alternative to restrictions on single-use plastics

These characteristics position corrugated cardboard as a material with low regulatory risk and high acceptance by conscious consumers.

Conclusion

The PAP symbol 20, while evolving into a more comprehensive labeling system under PPWR, will remain the key identifier for corrugated board in packaging waste management. For sustainability professionals, this transition presents both a compliance challenge and an opportunity to optimize the environmental footprint of their packaging portfolio.

Organizations that proactively adopt PPWR criteria — especially regarding recyclability and eco-design — will not only ensure their regulatory compliance, but will also benefit from reduced REP fees and improved perception by stakeholders and consumers.